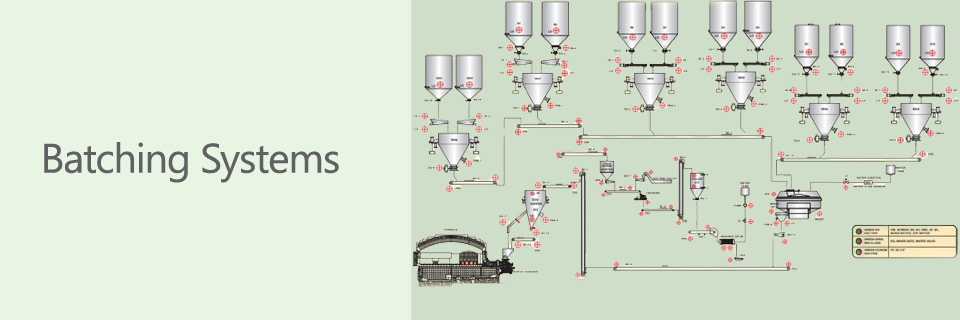

We are Manufacturer, Supplier of Load Cell, Batching Systems, Control Panels, PLC Automation, Tank Weighing, Checkweigher, Trading Product, Programmable Load Controller,Bagging Controller (Touch), Pune, Mumbai, Thane, Nashik, Aurangabad, Kolhapur, Sangli, Satara, Solapur,

Nagpur, Amaravati, Ahmednagar, Maharashtra.

|

|||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||