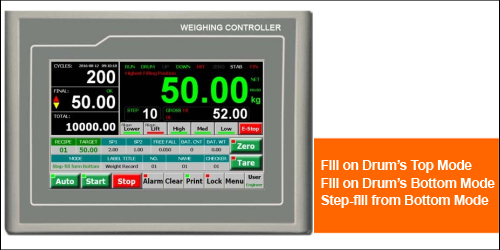

Main Features :

• EMC design with high anti-jam for industrial environment

• DC24V power input with reverse polarity protection

• Cortex-A8 CPU with 600MHz Clock, 128M Flash

• 7” [800×480] or 10.2” [1024×600] TFT touch panel

• 24-bit ∑-△ADC with internal resolution 1/1,000,000

• High sampling frequency 800Hz

• Special Anti-vibration Digital Filtering Algorithm for precise weighing, stable display and rapid response

• Target Batch Count & Target Batch Weight Control

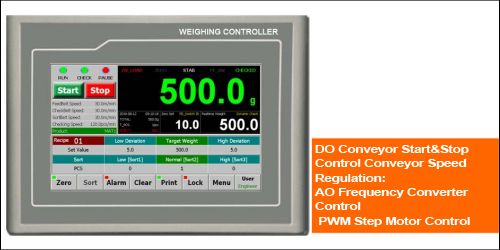

• Definable DI/DO/AO/COM[Communication Port]

• Recipe Number: 100

|